Our products cannot fail to convince, as with their specific properties Linz Textil yarns are suitable for a wide range of applications. Brilliant colours and pronounced skin friendliness ensure optimum climatic characteristics, and in addition our innovative product portfolio offers a wealth of exciting possibilities.

Our experienced team personifies professionalism, flexibility and competence, which in combination with efficient communications, ensures smooth procedures and first class service. Expert quality and application engineers work alongside our customers in order to improve production processes, raise quality and develop new end products.

Consulting: Our specialists are ready and waiting to provide competent advice that enables the rapid definition of the best yarn for the desired application.

Application technology: Linz Textil is a reliable partner whenever the efficiency of customer production processes is to be optimized. We provide on-site support, jointly prepare tailor-made solutions and offer assistance during implementation.

Development competence: Innovation is the key to continued market success. Consequently, our creative sales and development teams remain in constant touch with our customers, in order to ensure that their individual concepts can be coordinated with qualified fibre suppliers and thus achieve realisation.

Logistics: The Linz Textil name is synonymous with an outstanding delivery service and consistent first class quality.

Our experienced team personifies professionalism, flexibility and competence, thus forming the basis of our success.

Quality and Innovation

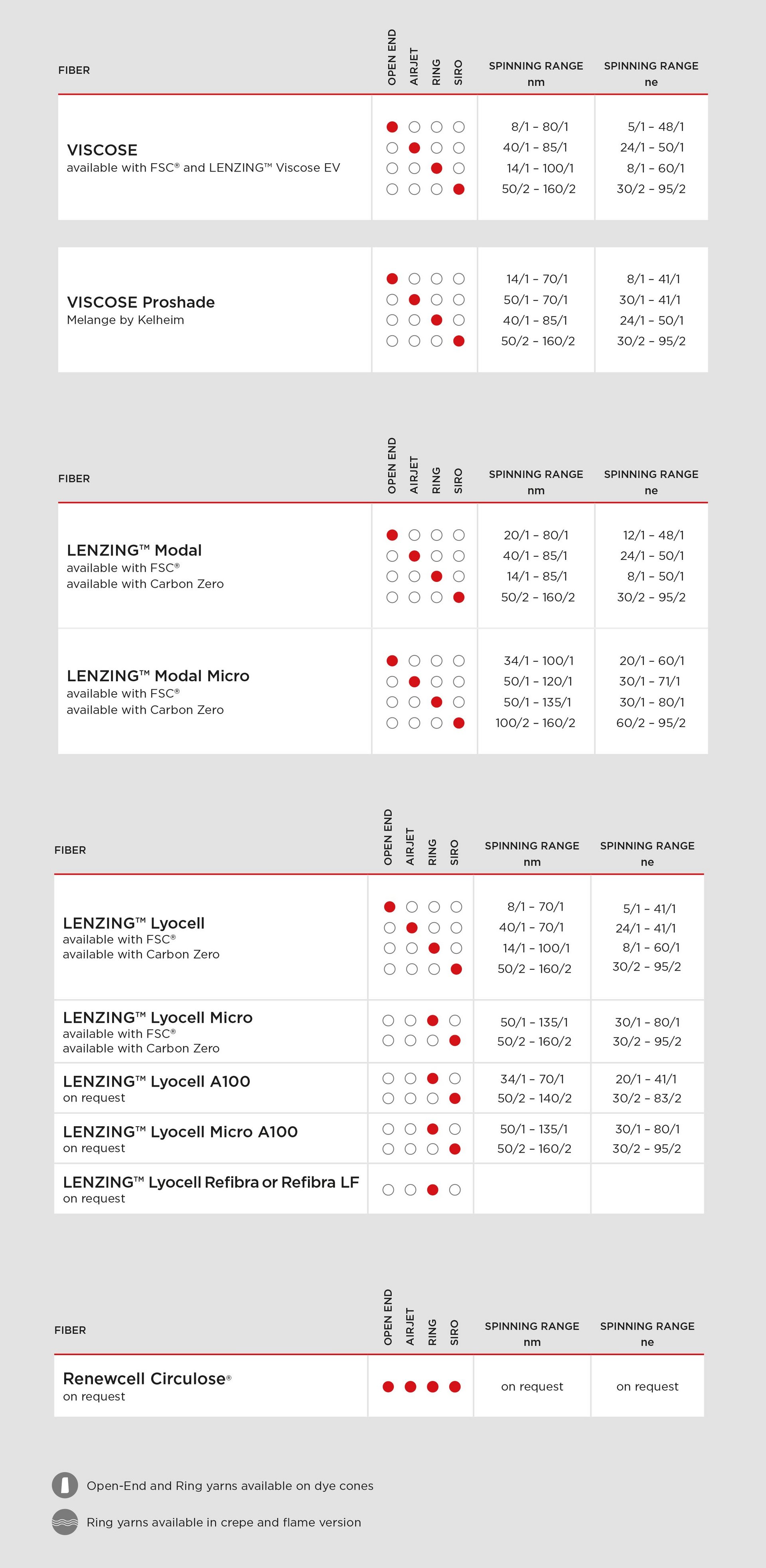

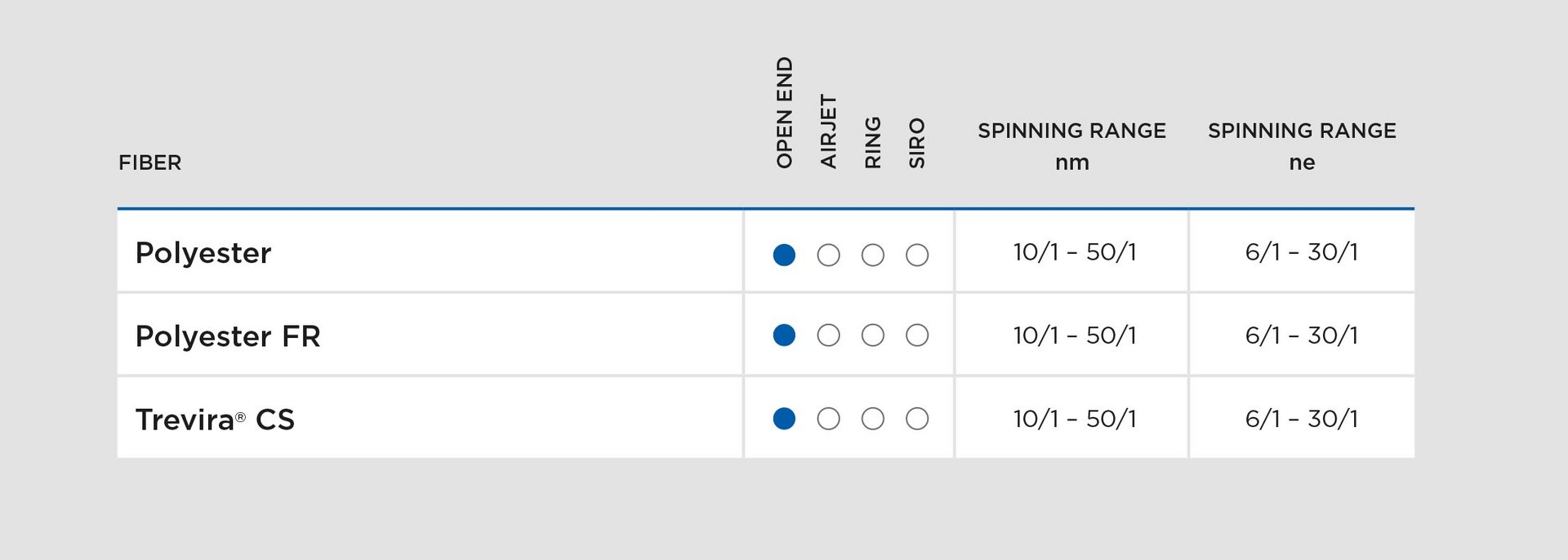

Linz Textil’s spinning mill employs state-of-the-art spinning technologies from machine manufacturers of global repute. This enables us to set new production benchmarks and deliver OE rotor, air jet, ring spun and SIRO yarns of the highest quality.

Linz Textil regards a clear service and orientation as a matter of course. Therefore, customers are involved in the planning and production process at an early stage, which ensures efficient results. Moreover, in tandem with the standard of service apparent during every phase of cooperation, constant quality consciousness guarantees exceptional end products.

Our innovative edge derives from our long-term partnerships with leading fibre producers and spinning technology suppliers. Consequently, spinning and fibre technology advances can be integrated into the production process at an early stage and innovative products are brought to market far more quickly.

The result?

Linz Textil is constantly one thread ahead of the competition!

![[Translate to English:] Mag. Friedrich Schopf [Translate to English:] Mag. Friedrich Schopf](https://www.linz-textil.at/fileadmin/user_upload/bilder/team/Schopf_0082.jpg)

Friedrich Schopf

CEO Linz Textil Holding AG and

MD Linz Textil GmbH

schopf[at]linz-textil.at

+43 732 3996-0

![[Translate to English:] Kristina Doppler [Translate to English:] Kristina Doppler](https://www.linz-textil.at/fileadmin/user_upload/bilder/team/Doppler_0150.jpg)

Kristina Doppler

Head of Sales, Linz/Klanjec Spinning Mill

doppler[at]linz-textil.at

+43 732 3996 DW 225

![[Translate to English:] Goran Ivekovic [Translate to English:] Goran Ivekovic](https://www.linz-textil.at/fileadmin/user_upload/bilder/team/Ivekovic_0650.jpg)

Goran Ivekovic

Production Manager, Klanjec Spinning Mill

goran[at]predionica-klanjec.hr

+385 49588 300

![[Translate to English:] Spulen [Translate to English:] Spulen](https://www.linz-textil.at/fileadmin/user_upload/bilder/spinnerei_klanjec/spulen_kalnjec.jpg)

![[Translate to English:] Harald Schneebaur [Translate to English:] Harald Schneebaur](https://www.linz-textil.at/fileadmin/user_upload/bilder/team/Schneebaur_0110_V2.jpg)

![[Translate to English:] Ing. Matthias Lucan [Translate to English:] Ing. Matthias Lucan](https://www.linz-textil.at/fileadmin/user_upload/bilder/team/Lucan_0307.jpg)