Welcome to Linz Textil!

Founded in 1838 under the name “Baumwoll-Gespunstfabrika”, Linz Textil celebrated its 175th jubilee in 2013. Therefore, the group’s development from its beginnings in the early days of the European textile industry and its development into an international group in the age of globalization represent an exemplary and virtually unprecedented story of success. Over the years, Linz Textil has mastered both historical and branch-related turbulence through a blend of tradition and innovation, experience and strategic foresight with the result that it currently enjoys an extremely solid market position.

Industrial Innovation

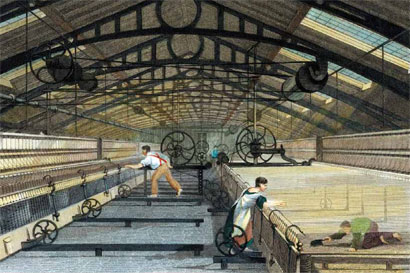

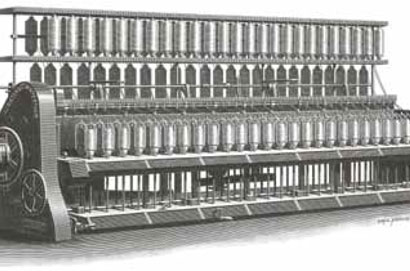

In the 18th century, textile production was still an entirely manual process, which meant that the simply insatiable “yarn hunger” of the looms could not be stilled by the soon obsolete spinning wheel. This need led to Hargreave’s spinning jenny (1763), Arkwright’s water frame (1769) and Crompton’s mule (1770), innovations that created a productivity explosion and paved the way to both branch industrialization and Britain’s role as a textile monopolist. Austria was a backmarker during this evolutionary process and in spite of their dominating market position, the large domestic cotton mills and the “k.k. priv. Wollzeugfabrik” in Linz failed to achieve the paradigmatic leap into the industrial age.

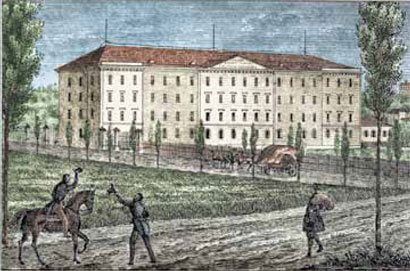

In Upper Austria, Johann Evangelist Grillmayr (1809–1881), who came from a poor, farming background, was to emerge as a textile pioneer. As a young man, he was employed in the trading company of the Hörzinger family, who sent him abroad to purchase yarns, where he gathered a precise knowledge of the machinery used in the mills. Upon his return to Linz, Grillmayr won the heart of Katharina, the recently widowed mistress of the Hörzinger enterprise. They married and in 1838 Grillmayr used his wife’s capital to buy into the “Baumwoll-Gespunstfabrika” (cotton spinning mill) of his friend Anton Wöss in Kleinmünchen in a move that denoted the birth of the company known today as “Linz Textil”. Grillmayr then set about designing and building ten large spinning machines, modelled on those that he had seen in England, and employed around one hundred workers in their assembly and installation. This marked the beginning of his rapid entrepreneurial rise.

The history of Linz Textil: the years 1838 to 1872

Grillmayr continued to enlarge his mill year by year and this vigorous expansion resulted in Wöss’ early withdrawal from the project in October 1841, which he regarded as being excessively risky. Grillmayr thus became the sole company owner and his mill, together with the adjacent Dierzer and Rädler works, soon contained two-thirds of all the spindles in Upper Austria. Even the revolution of 1848 did nothing to halt this upswing and the shops in Kleinmünchen continued to grow. Grillmayr named them after the origins of the machinery and the terms “Old English”, “New English” and the “Swiss” are still familiar today. In 1859, a mechanical weaving shop was also added.

Despite economic turbulence in the 1860s, when the textile industry was burdened with a drastic increase in raw material prices, Grillmayr’s business success remained uninterrupted and it was at this point that he decided to float his company on the stock exchange. Accordingly, the “Actiengesellschaft der Kleinmünchner Baumwollspinnereien und mechanischen Weberei” with share capital of 1.5 million gulden took over the plants and property of “Johann Grillmayr & Söhne” in Kleinmünchen and St. Peter. However, the Vienna Stock Exchange crash of 9 May 1873 was to thwart any ambitions that Grillmayr might have had and he was only able to narrowly save the company through the use of a vast amount of his personal fortune. His death in 1881 ended the direct influence of the Grillmayr family upon the Kleinmünchen spinning and weaving mill corporation.

The years 1872 to 1945

As a result of Johann Grillmayr’s spirited intervention, the newly founded Kleinmünchen spinning and weaving corporation was able to survive its first year and the stock exchange crash, while the founding bank and main stockholder, the Industrie- und Commerzialbank für Oberösterreich und Salzburg, collapsed. Moreover, in the next two decades between 1873 and 1896, which have gone down in both European and Austrian economic history as the “great depression”, the Kleinmünchen Actiengesellschaft nevertheless developed in excellent fashion. This fact is exemplified by the purchase in 1907 of the Löwenfeld & Hofmann merchant mill and its conversion into the “Mühlenspinnerei”. Since Grillmayr’s departure, the company was shaped largely by the director general Carl Reichel (1894–1910) and the technical director, Ludwig von Gallois (1890–1928), and during their time social progress such as the building of the “Aschensiedlung” housing took place. The Kleinmünchen company also survived World War I and the fall of the Habsburg monarchy by means of strategic investments (1917: Dierzer and Reutte weaving mill).

In view of the political climate, the fact that the economic position of the company in the 1920s was subject to major turbulence is hardly surprising. Nonetheless, the Kleinmünchen works continued to be one of the largest employers in Linz and in 1937 was the town’s biggest industrial enterprise. However, during 1938 the outlook was to alter fundamentally. For in the wake of the “Anschluss” of Austria with the German Reich, in its role as the “hometown of the Führer” Linz was to be turned into a metropolis with iron and steel (including the “Reichswerke Hermann Göring”) instead of textiles as its economic backbone. The Kleinmünchen company was forced to hand over land and the Zizlau mill, and had to battle increasingly against the war economy limitations upon the consumer goods sector. 1938 also brought a change to the corporation for until then, the Stern & Sohn banking house, which was designated as Jewish, owned some 4,000 of the 20,000 Kleinmünchner shares. These were taken over by the Creditanstalt, which by mid-1940 raised its holding to 11,200 shares (56%).

These were taken over by the Creditanstalt, which by mid-1940 raised its holding to 11,200 shares (56%). It then sold this entire package to Vereinigte Färbereien AG in Vienna, which in turn was fully owned by It then sold this entire package to Vereinigte Färbereien AG in Vienna, which in turn was fully owned by Schweizerische Druckereien und Färbereien Trust AG in Chur, Switzerland. In this way, Kleinmünchen became a “Swiss company”, which meant that although severely damaged by air raids in 1944/45, the company enjoyed special protection from the Allies in the chaotic days following the end of the war. In May 1945, only 176 of the former 1,400 employees remained. The weaving shop was shut down entirely and the spinning shop partially. Concrete slab production had been installed in the halls, while the looms were stored in the cellar. Nevertheless, a courageous new start commenced and great hopes were placed in Dr. Robert Thyll, the head of the Druckereien und Färbereien Trust AG. The motto was “new construction instead of reconstruction.”

The years 1945 to 1977

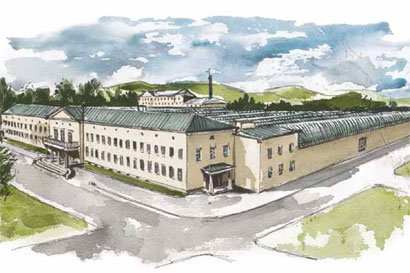

In spite of unfavourable preconditions and the damage to several company buildings, the Kleinmünchen workforce succeeded in restarting production just three weeks after the end of hostilities. The weaving shop, which had been closed in 1942 by official order, was reactivated using the looms stored in the cellar. Moreover, the Reutte weaving mill also recommenced production. As early as spring 1946, work began on the construction of a new large hall (shed hall) and administrative building. This was aided by ERP funding, although the shortage of building materials remained problematic. The bombed-out Zizlau and merchant mill power plants were also recommissioned and all in all, these massive, post-war reconstruction efforts also facilitated modern forms of production. However, as soon as the initial (domestic) hunger for textiles was satisfied in around 1950, a difficult period commenced with the founding of the European Economic Community of which Austria was not a member. Exports either stagnated or even shrunk and from 1955 onwards, in the heydays of the “economic wonder”, the company started to demonstrate an operative loss trend, which from 1960 onwards was to become permanent for twenty years.

The workforce shrunk with continuing rationalization, but nonetheless the increase in productivity was modest. The situation of the company was serious and further exacerbated by the extremely complex mix of the firms within the group. In addition, the 1960s were characterized by numerous legal actions on the part of shareholders and property sales for partial loss coverage. Furthermore, the semi-completed Kleinmünchen power plant was sold to ESG, the Linz utilities company.

By the mid-1970s, the point had been reached at which a choice had to be made between a fundamental reorientation of the company concept, or closure and the realization of its valuable real estate reserves and water rights. In 1972/73 an extensive investment programme was launched for the modernization of the spinning shops. But notwithstanding every effort, the company still made a loss in 1977.

The years 1977 to 2013

In the mid-1970s, liquidity shortages became an existential problem and the group’s reserves were already virtually exhausted due to the coverage of losses in past years. Furthermore, the suppliers had become restless. Fortunately, in order to avert a disaster at the very last moment, there was a readiness to accept massive structural change and with effect from 1 September 1977, Dr. Dionys Lehner, who had been appointed to the Supervisory Board in July 1976, was selected as the company chairman. His declared aim was to return the company to the black and he was given just two years in order to achieve it.

The nucleus of his management concept was formed by a new loan doctrine, which no longer saw debts as an investment opportunity undergirded by inflation, and a strategic focus on semi-finished products, which would go beyond the yarn and grey fabric segments. Other central aspects of this reorientation process were the new name, “Linz Textil AG” and a massive expansion and acquisition drive:

- 1982 Felixdorf spinning mill

- 1984 Telfs weaving mill

- 1985 Matrei spinning mill

- 1987 Reutte weaving mill (from the Group)

- 1992 Klarenbrunn spinning mill

- 1994 Landeck spinning mill

Apart from external, organic growth, Linz Textil expanded its operations through new buildings financed from its own resources. Among other features, the investment programme included the refurbishing of the grey fabric weaving shop in Linz during 1981 with an accompanying increase in output and the enlargement of the Linz spinning mill with an open end machine shop. This was followed in 1990 by the complete renewal of the shed spinning shop’s machine pool in Linz.

At the same time however, the Austrian textile industry was confronted with ever-increasing competitive pressure from Asia. In view of this situation, Linz Textil decided to abandon its expansion course and radically increase its equity ratio. Moreover, by the end of the 1990s Dr. Lehner, the company chairman, was convinced that should a major economic crisis occur, the global economy would be unprepared to deal with it. By contrast, Linz Textil would be ready.

Owing to the excellent preparations made, in spite of the crisis Linz Textil succeeded in developing production with low-cost structures at the locations in Klanjec/Croatia (2002) and Nanjing/China (2009). Moreover, the Vossen brand with its production facilities in Jennersdorf and Szentgotthárd/Hungary was purchased in 2004 with the aim of supplementing the product range with terry goods. In December 2009 and January 2010, three major fires caused by arson destroyed the entire logistics capacity of the Linz spinning shops. Reconstruction was unavoidable and was pursued by means of ambitious projects such as the renewal of the entire preparation facility and the installation of modern Rieter J20 air jet looms for viscose yarn production. These investments furnished the company with the flexibility required in a partly unstable market climate. The textile industry numbers among the world’s most globalized branches, but nevertheless, Linz Textil has been able to hold its own in the international markets.

From 2013

The 175th anniversary of Linz Textil was celebrated in 2013 with a festive gala at the Linz Textil headquarters. Numerous business partners and guests from business and politics were welcomed to this event.

In 2015, a major investment was made in the field of ultrafine cotton yarn at the Landeck location. This conceptual reorientation was the most comprehensive investment project in ring spinning in Europe at that time. A customer weaves a large percentage of the yarns produced at Landeck into African damask, which is the fabric used to make the traditional West African "Boubou" garment (see photo).

In 2016, the Linz (Nanjing) Viscose Yarn Co. Ltd. subsidiary in China, which operates a viscose spinning mill in Nanjing, was sold to a Chinese partner.

Spinning production at the Linz location was terminated at the end of May 2018 and partly relocated to the Predionica Klanjec d.o.o. subsidiary in Croatia. Yarn production capacity at this highly modern mill thus increased from 7,130 to 10,000 t per year.